Essential Techniques for Efficient LED PCB Design explores the intricacies involved in designing printed circuit boards (PCBs) specifically for light-emitting diodes (LEDs). This topic is not just pivotal in ensuring robust performance but also speaks to the larger context of energy efficiency and sustainability in modern products. Throughout this article, we will delve into the key components, techniques, and emerging trends in LED PCB design, helping you to grasp efficient methodologies that ultimately lead to superior lighting solutions.

1. What Is LED PCB Design?

So, what exactly is LED PCB design? It’s the meticulous process where engineers create layouts for printed circuit boards that accommodate light-emitting diodes. These diodes have rapidly become fundamental components in lighting technology, and the design of the PCBs that support them is crucial for enhancing their performance. But here’s the kicker—proper LED PCB design not only affects the efficiency and brightness of the LEDs but also plays a vital role in their longevity and reliability.

LED PCB design entails understanding the electrical and thermal demands of the components being used and ensuring that the materials and layout can meet those needs. For instance, PCBs must dissipate heat efficiently, as excessive heat can shorten the lifespan of LEDs. Various techniques, such as thermal via arrangements and appropriate substrate materials, come into play during the design process.

There are several applications of LED PCBs beyond simple lighting solutions, including in displays for TV and monitors, automotive lighting, and even wearable technology. As demand for LED solutions grows, mastering LED PCB design becomes increasingly critical for professionals in the field.

| Aspect | Description |

|---|---|

| Definition | Design process for PCBs that house LEDs |

| Importance | Influences performance, efficiency, and lifespan |

| Applications | Used in lighting, displays, automotive, and more |

2. Why Is Efficient LED PCB Design Crucial?

Why is efficient LED PCB design so important? The answer lies in the multitude of factors that affect both the performance of LED products and the overall manufacturing costs. Efficient design minimizes energy consumption, ultimately leading to more sustainable lighting solutions. What’s the real story? Well, an effective LED design not only enhances performance but also reduces costs and waste.

One of the primary advantages of efficient LED PCB design is its significant impact on energy consumption. Enhanced designs allow LED products to operate at higher efficiencies, converting more electrical energy into light rather than heat. As a result, consumers benefit from lower energy bills and a reduced carbon footprint.

Additionally, well-executed LED PCB designs contribute to the reliability and lifespan of the product. Components that are optimally spaced and thermally managed reduce thermal stress, which is a leading cause of failure in electronic devices. Also, understanding the relationship between thermal management and performance is critical for manufacturers, as superior designs can lead to fewer warranty claims and increased customer satisfaction.

Lastly, from an economic standpoint, companies benefit from an efficient design process as it can lead to cheaper production costs and higher profit margins. All in all, prioritizing efficient LED PCB design is crucial for a successful, competitive business strategy in the lighting industry.

| Benefit | Effect |

|---|---|

| Energy Efficiency | Reduces energy consumption and costs |

| Reliability | Increases product lifespan |

| Cost-Effectiveness | Lowers production costs and boosts profits |

3. What Are the Key Components of LED PCB Design?

What are the essential components that go into LED PCB design? Understanding these elements is foundational to creating functional and effective PCBs for LEDs. It’s not just about placing LEDs onto a board; the entire assembly must be considered.

Firstly, the LEDs themselves are the obvious primary component, with a variety of types available depending on the application. Different LED packages—such as surface mount devices (SMD) or through-hole—provide various benefits in terms of placement and heat dissipation.

Next up are resistors and capacitors, which play crucial roles in managing current flow and stabilizing voltage, respectively. Resistors limit the electrical current flowing through the LEDs, thus preventing damage and ensuring optimal performance. Capacitors, on the other hand, help provide a buffer against voltage spikes, ensuring consistent light output.

Don’t forget about the PCB itself! The choice of substrate material—like FR-4 (a flame-resistant glass-reinforced epoxy laminate) or aluminum—can greatly influence the thermal and electrical characteristics of the PCB. Thermal management components, such as thermal vias and pads, are also critical in ensuring heat effectively dissipates from the LEDs.

Finally, connectors and other interface components are vital in establishing connections to external circuits, ensuring seamless integration in larger systems. It’s important to see how all of these components work together harmoniously to create an efficient LED PCB design that delivers superior functionality.

| Component | Function |

|---|---|

| LEDs | Emit light, various types for different needs |

| Resistors | Manage current flow to prevent damage |

| Capacitors | Stabilize voltage to minimize spikes |

| PCB Material | Affects thermal and electrical performance |

| Thermal Components | Ensure effective heat dissipation |

4. How Do You Choose the Right PCB for LED Applications?

How do you select the right PCB for LED applications? The importance of this decision cannot be overstated, as it directly influences the performance, reliability, and efficiency of your LED products. Here’s where it gets interesting—every detail matters, from materials to layout, and the implications can range widely.

First, consider the type of PCB material. Common options include FR-4, which is widely used but may not manage heat as well as aluminum PCBs. Aluminum boards are advantageous for high-power applications, as they excel at heat dissipation, thus prolonging the lifespan of the LEDs. Knowing which substrate to use based on your thermal management requirements can greatly improve performance.

Next, think about the circuit layout and tracing. The design should promote efficient current distribution to all components while also minimizing the risk of overheating. A well-designed PCB layout will involve strategically placing components to ensure optimal heat flow and easier assembly.

Don’t forget about the environmental factors, too. If the LED application is intended for outdoor use or in harsh environments, selecting a PCB material that can withstand moisture, temperature fluctuations, and corrosion is essential.

Ultimately, selecting the right PCB for LED applications hinges on understanding the specific demands of your project. Get this right, and you’ll dramatically improve both the effectiveness and durability of your LED products.

| PCB Material | Characteristics |

|---|---|

| FR-4 | Good for basic applications, low thermal performance |

| Aluminum | Excellent heat dissipation, ideal for high-power |

| Flexible PCBs | Suitable for curved surfaces and compact designs |

5. What Are the Common Design Techniques for LED PCBs?

What common design techniques should you employ when creating LED PCBs? The success of your LED products depends greatly on the methodology you adopt during the design phase. Ready for the good part? By implementing effective design strategies, you can create high-quality PCBs that meet or exceed performance expectations.

One critical design technique is Design for Manufacturability (DFM). This approach focuses on making the PCB design simpler and less prone to defects, which helps in reducing production costs and time. This can involve adhering to specific guidelines, such as component spacing, pad sizes, and trace widths, thus ensuring that assembly is straightforward and reliable.

In addition, optimizing the layout for thermal efficiency is paramount. Techniques like utilizing thermal vias, implementing copper pours for heat distribution, and placing heat-sensitive components strategically can help manage temperatures effectively and prevent LED burnout.

Moreover, embracing a multi-layer PCB design can offer more routing space without increasing your board size. This method is particularly beneficial for minimizing electromagnetic interference (EMI) and ensuring signal integrity, especially in more complex LED applications.

Lastly, simulation software can be invaluable for testing thermal performance and circuit behavior prior to fabrication. Simulating your PCB design allows you to identify potential failures before investing in production, saving both time and resources.

By incorporating these design techniques into your practices, you can elevate the quality of your LED PCBs, ensuring they meet market demands and regulatory standards.

| Design Technique | Benefits |

|---|---|

| DFM | Simplifies manufacturing, reduces costs |

| Thermal Management | Prevents overheating and extends lifespan |

| Multi-layer Design | Minimizes size while improving performance |

6. How Do You Manage Heat in LED PCB Design?

How do you effectively manage heat in LED PCB design? Managing heat is crucial, as temperature fluctuations can dramatically affect the performance and reliability of your LEDs. So, what’s the real story? Implementing effective thermal management strategies can be the difference between success and failure in LED applications.

One of the primary techniques for heat management involves selecting the appropriate materials. For instance, using a metal-core PCB, particularly aluminum, allows for better thermal performance compared to standard FR-4 materials. The metal layer acts as a heat sink, drawing heat away from the LEDs and distributing it efficiently.

Next, consider the placement of components on the PCB. Grouping high-heat components together, along with proper thermal vias, allows for improved heat dissipation. Thermal vias connect different layers of the PCB and can help funnel heat away from critical components toward areas where it can be better managed or dissipated.

Additionally, employing thermal interface materials (TIMs) can facilitate better heat transfer between the LED and the PCB. These materials fill small air gaps and imperfections between surfaces, enhancing thermal conductivity and helping to keep the LED cool in operation.

Finally, designing for airflow can also play a role. If your product will be housed in a confined space, incorporating features such as vents or heat sinks can provide necessary airflow around the components.

By focusing on these heat management techniques in your LED PCB design, you’ll improve overall performance and ensure that your lighting solutions operate reliably over time.

| Heat Management Strategy | Benefit |

|---|---|

| Material Selection | Improves thermal performance |

| Component Placement | Enhances heat flow and dissipation |

| TIMs | Facilitates better heat transfer |

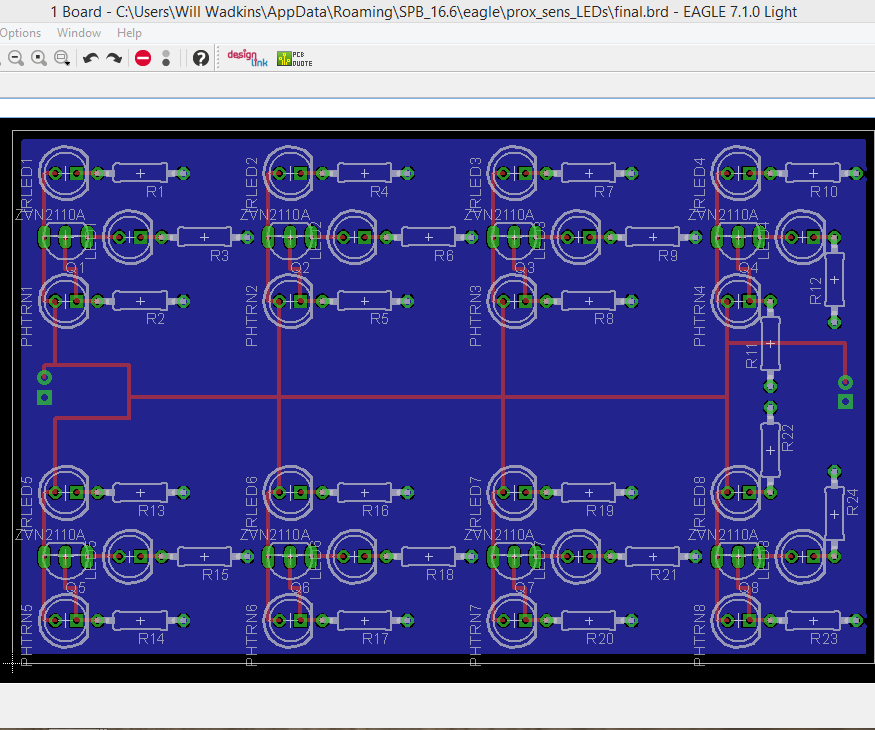

7. What Software Tools Are Recommended for LED PCB Design?

Which software tools are most effective for LED PCB design? The right software can make a significant difference in the quality and efficiency of your design processes. But here’s the kicker—choosing the right tools means choosing ones that align with your specific project requirements and budget.

Popular PCB design software includes Eagle, Altium Designer, and KiCAD, each offering unique features tailored to different user needs. Eagle is well-regarded for its user-friendly interface and is a favorite among hobbyists and small businesses. On the other hand, Altium Designer is robust and offers advanced features that cater to larger enterprises with more complex design needs.

For those on a budget, KiCAD is a free, open-source option that provides substantial capabilities for both beginners and advanced users. It’s not just economical; it also supports multi-layer designs and offers tools for simulation, making it ideal for efficient LED PCB design.

When selecting PCB design software, consider features such as design rule checks (DRCs), schematic capture capabilities, and simulation tools. Also, think about whether the software integrates well with other design tools you may be using, as this can streamline your workflow significantly.

Finally, make an effort to look for user reviews or forums discussing the pros and cons of specific tools. Online communities often provide insights into real-life application and usability that can influence your choice.

By leveraging the right software tools, you can simplify the design process and enhance the quality of your LED PCBs.

| Software Tool | Key Features |

|---|---|

| Eagle | User-friendly, good for small projects |

| Altium Designer | Advanced features for large teams |

| KiCAD | Free, open-source with substantial capabilities |

8. How Can You Ensure Design Compliance with Standards?

How can you ensure that your LED PCB design complies with industry standards? This aspect is vital, especially if you want your products to meet regulatory requirements and gain market acceptance. What’s the real story? Compliance with standards not only ensures safety but also enhances customer trust.

First, familiarize yourself with the relevant industry standards, such as IEC, IPC, and UL. These organizations provide guidelines on design practices, safety, and performance criteria that your LED PCB must adhere to. Understanding these standards from the outset can guide your design decisions and save you time during the certification process.

Next, ensure that you incorporate necessary safety features into your design, including overcurrent protection and adequate voltage ratings. Always aim to comply with electromagnetic compatibility (EMC) requirements to avoid interference with other electronic devices.

Testing your PCB prototypes against these standards before mass production is essential. This includes conducting electrical safety tests, thermal performance assessments, and mechanical reliability testing. Ensuring that your designs pass these tests is critical to moving forward in production.

Finally, keep thorough documentation throughout the design and testing phases. This documentation serves as proof of compliance and can be valuable if any issues arise during inspections or audits.

By focusing on compliance from the beginning, you’ll ensure that your LED PCB designs are not only functional but also safe and trustworthy for consumers.

| Compliance Aspect | Importance |

|---|---|

| Industry Standards | Ensures safety and performance |

| Safety Features | Minimizes risks and conforms to regulations |

| Documentation | Essential for proving adherence to standards |

9. What Challenges Might You Encounter in LED PCB Design?

What challenges are commonly faced in LED PCB design? Understanding these challenges is key to overcoming them effectively and can lead to more successful product outcomes. Ready for the good part? By anticipating these hurdles, you can strategically approach your design process.

One of the main challenges is managing heat dissipation, which we’ve discussed previously. While there are strategies to enhance thermal performance, unexpected heat issues can still arise, demanding further attention and design optimization.

Another challenge is ensuring component compatibility, especially when using various LED types or integrating existing PCB designs with new components. Mixing and matching components can lead to issues such as mismatched voltage ratings or current handling capabilities, which can compromise performance.

Additionally, as designs become more intricate, maintaining signal integrity can be difficult. High-speed signals can encounter interference and degrade performance if not designed properly. Ensuring the PCB layout minimizes electromagnetic interference (EMI) should always be a priority.

Lastly, costs can also pose a challenge. As complexity increases, so can the manufacturing costs due to the additional processes and materials required. It’s imperative to balance performance and cost-effectiveness in your design decisions.

By recognizing and proactively addressing these challenges, you can simplify your design process and enhance the chances of creating a successful LED PCB.

| Challenge | Solution |

|---|---|

| Heat Dissipation | Optimize thermal management strategies |

| Component Compatibility | Ensure specifications align and test compatibility |

| Signal Integrity | Use good layout practices to minimize interference |

10. How Can Prototyping Enhance LED PCB Design?

How does prototyping benefit LED PCB design? Prototyping serves as a critical step that allows designers to test their concepts before committing to production. What’s the real story? Creating prototypes helps identify issues early, leading to improved design quality and reduced costs.

The first advantage of prototyping is the ability to evaluate functionality. By developing a physical PCB, you can assess performance attributes such as thermal management and LED output under real-world conditions. This allows for immediate adjustments, which is essential for ensuring desired performance.

Additionally, prototypes allow you to identify usability issues in your design. User feedback is invaluable; it can uncover elements that may not work as intended in a practical setting. By incorporating this feedback, you can refine the design for ease of use and improved functionality.

Tools such as 3D printing or PCB fabrication services enable rapid prototyping, allowing for quick iterations and adjustments. This approach not only speeds up the development process but also encourages a culture of innovation by allowing designers to experiment freely.

In summary, investing time and resources into prototyping can streamline your LED PCB design efforts, resulting in a higher-quality end product while saving cost and time in the long run.

| Prototyping Benefit | Description |

|---|---|

| Functionality Testing | Evaluate performance in real-world conditions |

| User Feedback | Identify usability issues |

| Rapid Iteration | Quickly adjust design based on test results |

11. What Testing Methods Are Used in LED PCB Design?

What testing methodologies are essential in LED PCB design? Effective testing is paramount to ensuring that your LED products meet expected performance and safety standards. Ready for the good part? Implementing a comprehensive testing strategy can save you numerous headaches down the line.

Firstly, functional testing assesses whether the PCB operates as intended under various conditions. This includes checking for correct voltage levels, current flow, and LED brightness. Proper functional testing ensures that all components interact as designed, confirming the performance of your product in real-world scenarios.

Thermal testing is similarly crucial. By monitoring temperatures throughout the operation of the PCB, you can identify potential overheating issues. This insight helps refine your thermal management strategies and guarantees that your LED lights run efficiently without degrading performance over time.

Also, reliability testing plays an integral role. This involves subjecting the PCB to stress tests emulating extended usage and extreme conditions. Reliability testing can uncover weaknesses in the design, providing critical information before full-scale production.

By embracing these testing methodologies, you’ll establish confidence in your LED PCB designs, ensuring they operate at optimal performance and meet consumer expectations.

| Testing Method | Purpose |

|---|---|

| Functional Testing | Ensures operation under varied conditions |

| Thermal Testing | Monitors temperatures to prevent overheating |

| Reliability Testing | Identifies weaknesses for long-term performance |

12. How Does LED PCB Design Impact Product Performance?

How does the quality of LED PCB design affect the overall performance of the final product? Understanding this connection is vital for creating effective and reliable LED solutions. This is where it gets interesting—small details in the design can lead to significant changes in the end-user’s experience.

One primary consideration is the precision of component placement. Optimal placement directly influences electrical performance and reliability. Accurate positioning ensures consistent current flow to the LEDs, while poor placement can lead to flickering, uneven brightness, or even failure.

Thermal management is another critical area where design impacts performance. Efficient heat dissipation directly correlates with LED longevity. A properly designed PCB will manage thermal loads effectively, safeguarding the LEDs from excessive heat, which can lead to burnout or diminished brightness over time.

Signal integrity also surfaces as a significant factor. A well-designed PCB minimizes electromagnetic interference and maintains integrity throughout the circuit. This aspect ensures that the LEDs operate reliably, without glitches, and provide the expected light output.

Ultimately, ensuring a high-quality LED PCB design equates to delivering a superior product. The consequences of neglecting design details can result in costly failures, reduced performance, and ultimately, customer dissatisfaction.

| Design Impact | Performance Effect |

|---|---|

| Component Placement | Influences current flow and reliability |

| Thermal Management | Affects LED lifespan and brightness |

| Signal Integrity | Ensures consistency and prevents glitches |

13. What Are the Latest Trends in LED PCB Design?

What trends are shaping the future of LED PCB design? Staying informed about these trends ensures that you remain competitive in an ever-evolving industry. But here’s the kicker—adapting to new technologies can lead to improved performance and market differentiation.

One major trend is the shift toward sustainability. Designers are increasingly aware of the environmental impact of materials and processes, leading to the adoption of eco-friendly components. This movement not only aligns with consumer preferences but also minimizes ecological footprints.

Additionally, advancements in automation are transforming the design and fabrication processes. Automated assembly lines and design tools can significantly enhance efficiency while reducing human error. As companies look to scale, embracing automation becomes essential for maintaining quality and reducing production times.

Intriguingly, the integration of smart technologies is also on the rise. The demand for IoT-capable LED products is growing, allowing users to control lighting through mobile applications. This trend requires innovative PCB designs that accommodate controllable features while ensuring robust performance.

Lastly, the use of advanced materials continues to expand. New composite materials with superior thermal management properties or flexibility showcase the potential for innovative designs tailored to diverse applications.

By keeping an eye on these trends, you can sharpen your competitive edge and create LED PCB designs that meet the demands of both the market and consumers.

| Trend | Key Implication |

|---|---|

| Sustainability | Reduces environmental impact |

| Automation | Enhances efficiency and minimizes errors |

| Smart Technology | Expands demand for IoT-capable products |

14. How Can You Stay Updated on LED PCB Design Best Practices?

How can professionals remain current on best practices for LED PCB design? Keeping up with the latest industry developments is crucial in sustaining a competitive edge. What’s the real story? Engaging with educational resources and professional networks can significantly boost your knowledge and skills.

Subscribing to industry publications and online journals is a critical first step. Sources like the IPC magazine or LED professional review articles provide invaluable insights into recent technological advances and design practices.

Joining professional organizations such as the IPC or IEEE can also facilitate networking with peers, accessing training resources, and participating in workshops. These platforms offer opportunities for continuous education, showcasing the latest tools and techniques in PCB design.

Participating in webinars and online courses is another valuable avenue. Many organizations and experts share their knowledge through structured learning, focusing on current trends or specific design methodologies.

Lastly, engaging with online forums and communities can provide practical insights. Real-world experiences shared by fellow designers often reveal troubleshooting tips and innovative techniques that aren’t available in textbooks.

By proactively seeking knowledge and engaging with the LED PCB design community, you can remain ahead of the curve in a rapidly evolving industry.

| Learning Method | Benefit |

|---|---|

| Industry Publications | Provides insights into trends and innovations |

| Professional Organizations | Facilitate networking and training opportunities |

| Webinars & Online Courses | Structured learning from industry experts |

15. What Future Developments Should You Expect in LED PCB Design?

What future developments can we anticipate in LED PCB design? As technology progresses, the LED PCB landscape is poised for significant transformations. Ready for the good part? These advancements have the potential to redefine what’s possible in lighting and beyond.

One major development is the continued improvement of materials. Innovations in substrates and thermal interface materials promise enhanced performance and efficiency. As manufacturers explore alternatives to traditional options, we can look forward to products that dissipate heat even more effectively.

Also, as smart technology integration grows, PCB designs must evolve to incorporate IoT capabilities. Expect to see more LED products equipped with sensors and software that enable remote monitoring and control, aligning with the smart home and smart city trends.

Moreover, the incorporation of machine learning and artificial intelligence within design tools shows promise for the future. These technologies can help automate design processes, reducing human error and improving efficiency, ultimately leading to more sophisticated LED solutions.

Finally, sustainability will continue to lead the charge in product development. Pressure from consumers and regulators will drive manufacturers to adopt eco-friendly practices and materials more broadly.

In conclusion, the future of LED PCB design looks bright. By staying informed and embracing these developments, you can position yourself as a leader in this exciting industry.

| Future Development | Potential Impact |

|---|---|

| Advanced Materials | Improved performance and heat management |

| IoT Integration | Enhanced control and functionality |

| AI in Design Tools | Streamlined processes and reduced errors |

FAQ Section

Q1: What is LED PCB design?

LED PCB design is the process of creating layouts for printed circuit boards that are specifically intended to hold light-emitting diodes, ensuring optimal efficiency and reliability.

Q2: How does thermal management work in LED PCB design?

Thermal management in LED PCB design involves using specific materials and layouts that facilitate the effective dissipation of heat produced by the LEDs, ensuring they operate efficiently without overheating.

Q3: What are the key components of LED PCB design?

The key components include LEDs, resistors, capacitors, the PCB substrate material, and thermal management components, all of which work together to ensure optimal performance.

Q4: What testing methods are applied in LED PCB design?

Essential testing methods include functional testing, thermal testing, and reliability testing, all aimed at ensuring the PCB performs correctly and maintains longevity.

Q5: How can prototyping enhance LED PCB design?

Prototyping allows designers to create physical models of their PCBs to test and validate functionality, gather user feedback, and identify potential improvements before full-scale production.