Professional LED PCBA Assembly Manufacturer in China

From PCB fabrication to full PCBA assembly, XLY provides high-quality, fast-turnaround services for LED lighting manufacturers worldwide.

Comprehensive LED PCBA Assembly Services

We provide complete PCB fabrication, SMT assembly, and functional testing services designed specifically for LED lighting applications.

PCB Fabrication

Custom LED PCB manufacturing: FR-4, Aluminum, and Copper base

High thermal conductivity options for high-power LED applications

Precise copper thickness control (0.5–3oz)

Fast prototyping available in 3–5 days

Supports single-layer, double-layer and multi-layer LED boards

SMT Assembly

Fully automated SMT production lines for LED PCBA

High-speed pick-and-place capability for LED chips, resistors, ICs

Component size compatibility: 0201 to 5050

Reflow soldering with strict temperature profiling for LED stability

Supports COB, DOB, and mixed-technology assembly (SMT + DIP)

Testing & Packaging

AOI inspection for all SMT assemblies

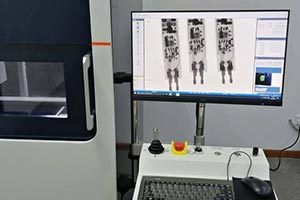

X-ray inspection for critical components and solder joints

Aging test & functional testing for LED drivers and modules

DIP assembly and manual finishing options

Final packaging & labeling customized for your production line

SMT Manufacturing Strength

High-Precision SMT Assembly for LED Modules and Driver PCBA

① High-Precision SMT Capability

8 SMT automated production lines

Placement accuracy: ±0.03 mm

0201 / 0402 / 0603 LED components supported

Capable of COB LED, DOB modules, driver ICs, MOSFET, diodes, capacitors

Dual-sided SMT assembly

Capacity: 3 million LED components placed per day

Supports small-batch prototyping → mass production without switching lines

② Smart & Automated SMT Lines

Fully automatic solder paste printer + SPI inspection

High-speed Yamaha / JUKI pick & place machines

Nitrogen Reflow Oven for high-reliability LED soldering

Auto-feeding material system for stable production

Traceability system:barcode & data tracking

Real-time production monitoring (AOI defect feedback to the printer → auto adjustment)

③ Quality Assurance & Reliability Tests

100% SPI / AOI inspection

X-ray for hidden solder joints (LED COB, IC driver)

Aging test for DOB / LED modules

High-temp, thermal shock test

Functional test for driver PCBA

Resistance / voltage / current check

High-speed camera inspection for LED brightness consistency

ESD control throughout production

ERP tracking for every board

Complete SMT Manufacturing Process

Fully automated workflow ensuring precision, consistency, and reliable LED PCBA quality.

Solder Paste Printing

SPI Inspection

SMT Pick & Place

Reflow Soldering

AOI Inspection

X-ray

Wave Soldering

Aging Test

Why Choose Our SMT Assembly

High-Precision, Reliable and Cost-Effective Solutions for LED Applications

4 Core Advantages of Our SMT Assembly

With our advanced production lines, strict quality control, and a highly experienced engineering team, we ensure every LED PCBA meets the highest standards for reliability and performance. Partner with us to accelerate your project development and reduce overall production costs.

1. High-Precision SMT

Accurate placement down to ±0.03 mm for stable LED performance.

3. Strict Quality Control

100% AOI, SPI, X-ray and aging tests for reliable PCBA output.

2. Fully Automated Production

Advanced Yamaha/JUKI SMT lines ensure consistent mass-production quality.

4. Fast Lead Time & Cost Savings

Quick prototyping and optimized production to reduce your total cost.

Application Areas

Cooperation Process

From Requirements to Mass Production — Simple, Clear, Efficient.

- Step 1 — Project Inquiry

Send product requirements, drawings, files, or sample photos.

- Step 2 — Engineering Evaluation

Our engineers check the BOM, Gerber, functions and provide a quotation.

- Step 3 — Sample Confirmation

We make prototypes for verification before mass production.

- Step 4 — Order & Production

SMT assembly, DIP, testing and full-line production.

- Step 5 — Quality Inspection

100% functional testing and appearance inspection.

- Step 6 — Delivery & After-Sales

Fast shipping and long-term technical support.

What The Say About XLY

rusted by Global LED Brands for High-Quality SMT Assembly

XLY

"The quality of LED PCBA is excellent. The automated SMT lines ensure consistency in every batch. Communication and support are top-notch."

XLY

"We have been working with XLY for over 2 years. Their fast prototyping and strict quality control save us time and cost in production."

XLY

"Reliable partner for our LED lighting projects. XLY’s engineering team provides professional support and ensures all orders meet our requirements."

XLY

Years Of Experiences

Countries Served

Satisfied Customers

On-Time Delivery

Common Questions

Most Popular Questions

Our MOQ is flexible. For prototypes, we can start from small batches, and for mass production, we support large-scale orders efficiently.

We typically complete SMT prototypes within 3–5 days, depending on complexity.

We accept Gerber files, BOM lists, and PCB drawings. If you provide a sample, we can also reverse-engineer for production.

Yes, we can source all necessary components according to your BOM and ensure quality and timely delivery.

Yes, our SMT lines support 0201–5050 components, COB LEDs, DOB modules, ICs, MOSFETs, and other surface-mount devices.

We have 100% SPI, AOI, X-ray inspection, and aging tests, plus functional testing for drivers and LED modules. Every batch is tracked for reliability.

Typically, 7–10 days for standard PCBA production. Complex orders may take longer, depending on quantity and customization.

Yes, we provide custom design, engineering support, and DFM optimization for LED modules, driver boards, and other PCBA requirements.

Yes, we provide technical support, troubleshooting guidance, and assistance with future orders to ensure your production runs smoothly.

We ship worldwide, covering over 60 countries, including North America, Europe, the Middle East, and Southeast Asia, with flexible shipping options (DAP/DDP).

Send us a message

Let's Connect and Collaborate

xxx@xly8818.com Leo

hjy@xly8818.com Emma

wxj@xly8818.com Ivy

Phone:+86 15302778509 Leo

Phone:+86 19068621295 Emma

Phone:+86 15361027735 Ivy

Shenzhen Xinlongye Electronic Technology Co., Ltd. Room 503, Building A, Baitong Technology Innovation Industrial Park, Houting Community, Shajing Street, Bao’an District, Shenzhen, Guangdong, China

"XLY's SMT assembly is fast, precise, and reliable. Their team helped us optimize our PCB design and delivered high-quality boards ahead of schedule."