LED PCB Solutions We Provide

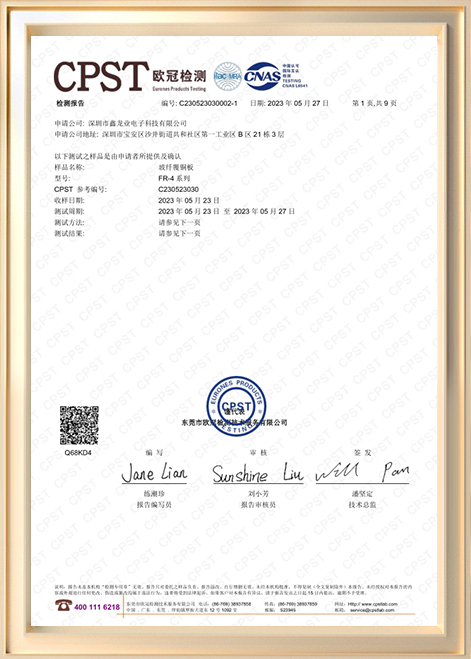

FR-4 LED PCB

Standard FR-4 PCB (Cost-Effective Solution)

The most versatile choice for general lighting applications where ultra-high heat dissipation is not critical. FR-4 offers excellent electrical insulation and mechanical strength at a competitive price point.

• Best For: LED Displays, Traffic Lights, Controllers, and Decorative Light Strips. • Key Advantage: Mature technology with lower cost and multilayer capabilities (up to 20+ layers).

Technical Specifications:

Material: Glass-reinforced epoxy laminate (FR-4)

Thermal Conductivity: 0.3 W/m·K (Standard)

Tg Value: TG130 / TG150 / TG170 (High TG available)

Layer Count: 1 – 4 Layers (Common for LED), up to 20 Layers

Copper Thickness: 0.5oz – 3oz

Application Scenarios

Electronic Toys

Decorative & Accent Lighting

Backlight Modules

ALUMINUM LED PCB

Aluminum MCPCB (High Thermal Performance)

XLY’s Flagship Product. Designed specifically for high-power LEDs requiring efficient heat dissipation. The aluminum metal core transfers heat 5-10 times faster than FR-4, preventing overheating and significantly extending the lifespan of your LED chips.

• Best For: Street Lights, Downlights, Spotlights, Grow Lights, and Industrial High-Bay. • Key Advantage: Superior thermal management to ensure stable LED performance.

Technical Specifications:

Thermal Conductivity: 1.0 W/m·K / 2.0 W/m·K / 3.0 W/m·K

Metal Base: Aluminum Alloy (5052 / 6061)

Breakdown Voltage: 3000V – 6000V (Hi-Pot Test Passed)

Board Thickness: 0.6mm – 3.0mm (Standard: 1.6mm)

Surface Finish: HASL / OSP / ENIG / Immersion Silver

Application Scenarios

LED Street Lights

Industrial High Bay Lights

Floodlights / Spotlights

COPPER LED PCB

Copper Core PCB (Premium Thermal Solution)

The ultimate solution for extreme thermal management. When aluminum isn’t enough, Copper Core PCBs offer the highest thermal conductivity in the market. Ideal for applications with extremely high power density.

• Best For: Automotive Headlights (EV), Military Lighting, UV curing, and Ultra-High Power Projectors. • Key Advantage: Direct heat path with Thermo-electric Separation technology.

Technical Specifications:

Thermal Conductivity: ~390 W/m·K (Copper Base Material)

Technology: Thermo-electric Separation (SinkPAD) available

Copper Thickness: Heavy Copper options (up to 12oz)

Structure: Circuit Layer + Dielectric Layer + Copper Core

Durability: Exceptional mechanical durability and heat resistance

Application Scenarios

Car Headlights & Fog Lamps

Medical Equipment

Stage Lighting Systems

Our Advantage – Full PCB Manufacturing Capability

⚡ Fast Production, Guaranteed Quality

72-Hour Prototyping

Get your PCB samples ready in just 72 hours, allowing you to test and validate your designs faster.7–10 Days Mass Production

Once your prototype is approved, we can move into full-scale production within 7–10 days, ensuring speed without compromising quality.

✅ Shorter lead times mean faster time-to-market.

✅ In-house production ensures stable quality and cost control.

✅ Perfect solution for urgent projects and bulk orders.

Send us your C.V.

Do you want to work with us? Please, send your CV to 👉 XLY

24/7 One-on-One Service ✅

Production Process

At XLY-LED PCB, we control the entire PCB manufacturing process in-house. From raw copper-clad laminate pressing, cutting, circuit imaging, ink printing, etching, and solder mask to silkscreen printing, profiling, and final inspection — every step is managed under strict quality control.

By mastering the full production chain, we ensure:

Stable Quality – Consistent standards from raw materials to finished boards.

Cost Efficiency – Reduced outsourcing costs, saving 20–30% for our clients.

Fast Lead Time – In-house production shortens delivery cycles significantly.

Reliable Supply – Comprehensive control guarantees on-time delivery for every order.

This end-to-end capability makes us not only a PCB supplier but also a trusted manufacturing partner who delivers value, reliability, and efficiency to your business.

Full-Process Manufacturing

1. Raw Material Preparation (CCL)

2. Raw Material Cutting

3. Drilling

4. Circuit Imaging

5. Circuit Etching

6. Solder Mask Application

7. Silkscreen Printing

8. Surface Finishing

9. Profiling / CNC Routing

10. Electrical Testing

11. Final Inspection & QA

12. Packaging & Shipping

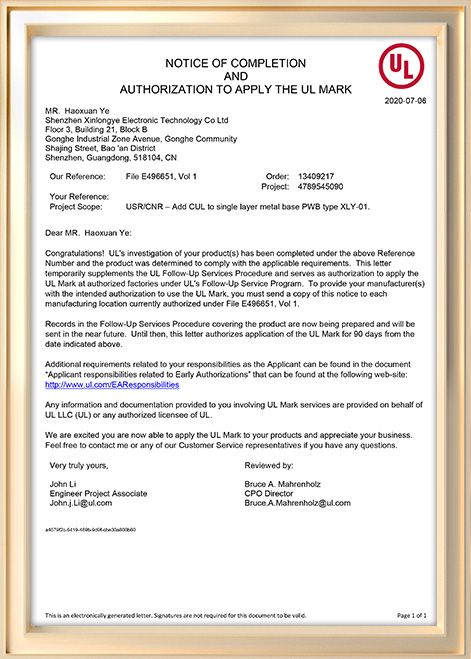

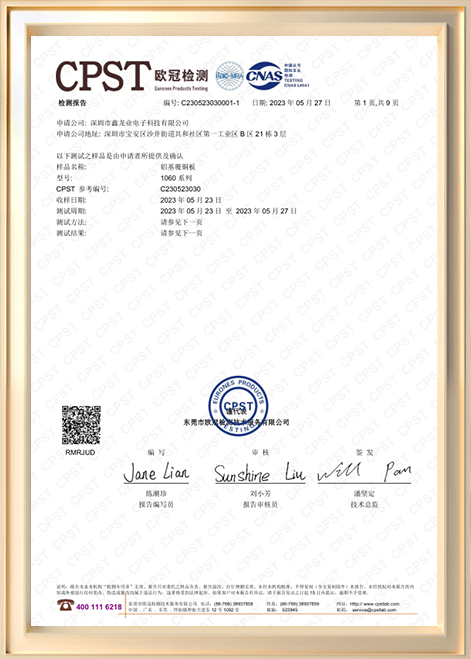

Our Recognitions

Our certified quality and compliance ensure reliable PCB solutions worldwide

How to Collaborate | Our PCB Process

Cooperation Process

1️⃣ Select Product

Customer Action: Browse our PCB catalog or contact us for professional advice.

We Provide:

Product specifications (size, layers, materials)

Recommendations for the PCB type that suits customer needs (high-frequency, aluminum, multi-layer, etc.)

Customer Value: Quickly find the most suitable product, reduce selection errors.

2️⃣ Provide Requirements

Customer Action: Submit PCB design parameters or fill in the requirement form.

We Provide:

Requirement form template (dimensions, layers, hole size, electrical specs)

Option to upload schematics, Gerber files, or reference drawings

Gerber file design service upon request

Customer Value: Accurate communication, avoid design errors.

3️⃣ Sample Confirmation

Customer Action: Receive samples, confirm appearance, dimensions, and functionality.

We Provide:

Sample production and fast delivery

Technical guidance for understanding sample parameters or functions

Sample testing instructions (electrical test, solderability check)

Customer Value: Confirm before mass production, minimize risk.

4️⃣ Mass Production

Customer Action: Confirm sample and place bulk order.

We Provide:

Production schedule and progress tracking

Strict quality inspection (AOI, flying probe testing, etc.)

Photos or videos of production progress for customer review

Customer Value: Full transparency, peace of mind.

5️⃣ Delivery

Customer Action: Confirm shipping information.

We Provide:

Secure packaging and fast shipping

Tracking number and estimated delivery time

Delivery documents (packing list, quality inspection report)

Customer Value: Timely receipt, guaranteed quality.

6️⃣ After-Sales Support

Customer Action: Contact us if issues or questions arise after receiving the PCBs.

We Provide:

Technical support for troubleshooting or application guidance

Warranty and replacement service for quality issues

Regular follow-ups for long-term cooperation and product improvement

Customer Value: Peace of mind, reliable support throughout product lifecycle

Trusted by Global LED Manufacturers

Industry Coverage

What We Bring to Your Business

“Trusted by LED Manufacturers, SMT Factories, and Global Distributors.”

LED Manufacturers

- Reliable PCB solutions

- Fast prototyping and mass production

- Efficient thermal management

- Comprehensive one-stop service

- 100% test before shipping

SMT Assembly Factories

- Consistent PCB quality

- Short lead times to keep your production

- Flexible customization

- Reduce rework and improve yield rates

- Worry-Free After-Sales Service

PCB Distributors

- Competitive pricing

- Stable supply to meet your order

- Technical support

- Flexible order quantities

- Hassle-Free After-Sales Support

What Our Clients Say

“XLY-LED PCB delivered prototypes in just 72 hours and helped us launch our new product on time. Their speed is unmatched.”

Procurement Manager

European LED Manufacturer

“The PCB quality is consistent and reliable, which keeps our SMT assembly lines running smoothly without delays.”

Production Supervisor

Middle East SMT Factory

“By working with XLY, we reduced material and labor costs by nearly 25%, while still ensuring high quality for our customers.”

CEO

U.S. PCB Trading Company

“Their engineering support and customization service saved us weeks of development time. The team truly understands our needs.”

R&D Engineer

Asian LED Lighting Brand

“Stable delivery and excellent after-sales service make XLY one of our most trusted partners in the supply chain.”

Supply Chain Manager

German Industrial Lighting Company

“For our high-power LED applications, XLY’s copper-based PCBs provided outstanding thermal management and reliability.”

Technical Director

North American Medical Device Company

Frequently Asked Questions

Service FAQs

We can provide prototype samples within 72 hours, and mass production takes 7–10 days depending on order quantity and complexity.

Yes, we offer 24/7 one-on-one support. Our sales and engineers will follow your project from design to delivery.

We have flexible MOQs. For prototypes and small batches, we can start with a low quantity to support your testing needs.

Yes, we offer global delivery via DHL, FedEx, UPS, and sea freight. You can choose the most suitable logistics method.

We usually accept T/T, PayPal, and L/C for larger orders. Flexible payment methods are available depending on your order.

Product FAQs

We offer FR-4, Aluminum, Copper, Double-Sided, and FPC LED PCBs, covering both cost-effective and high-power applications.

Yes, we support OEM & ODM services. You can send us Gerber files, schematics, or design requirements, and our engineers will assist you.

We offer HASL, ENIG, OSP, Immersion Silver, and Gold Plating, depending on your project needs.

All PCBs go through 100% electrical testing, AOI, and final inspection before shipment. We are certified with ISO, UL, and RoHS.

Yes, we offer free samples for evaluation (you only cover the shipping cost).

Did not find what you're looking for ?

Don't worry, send your inquiry to us

“We are committed to answering your questions and offering the best solution for your needs.”